In today’s rapidly evolving technological landscape, the boundaries between mechanical systems and electronics are increasingly blurred. Enter Mechatronic Design—a multidisciplinary engineering approach that combines mechanical engineering, electronics, computer science, and control systems to design and build intelligent products and systems. Mechatronic Design lies at the heart of modern automation, robotics, automotive systems, and advanced manufacturing, driving innovation across industries.

What is Mechatronic Design?

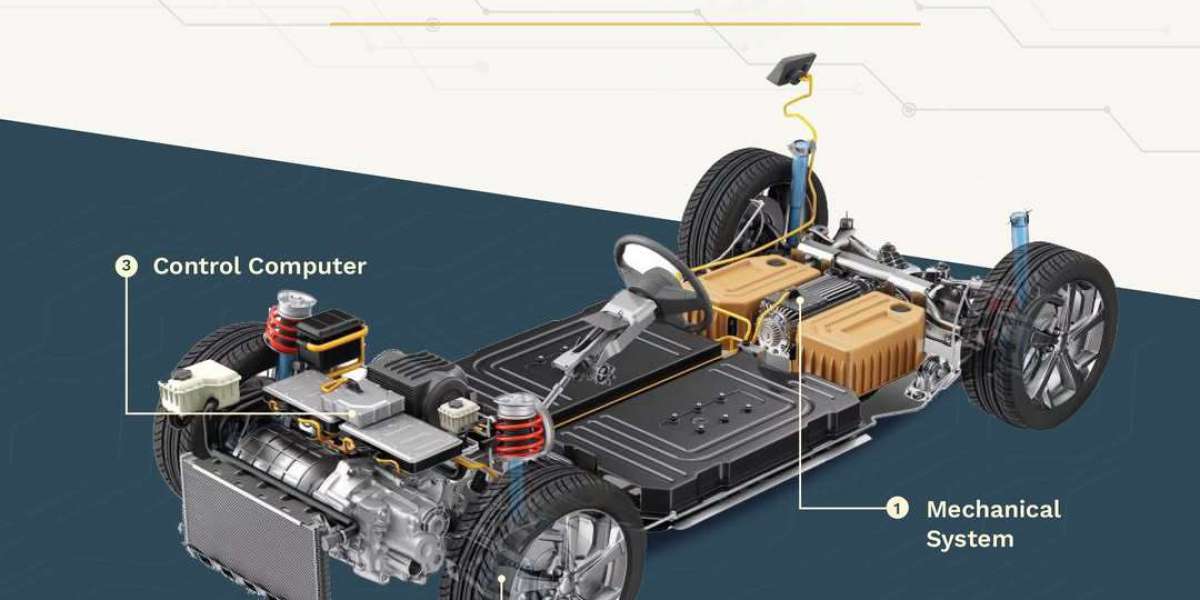

Mechatronic Design is the process of creating products that incorporate mechanical components with electrical and electronic elements, governed by intelligent control systems. This integration enables the development of smart devices that can sense, analyze, and act with precision. Examples range from everyday items like washing machines and drones to advanced industrial robots and autonomous vehicles.

The term “mechatronics” originated in Japan in the 1960s, combining the words “mechanics” and “electronics.” Today, it has evolved into a key enabler of Industry 4.0 and intelligent automation.

Core Disciplines in Mechatronic Design

Mechatronic systems blend multiple engineering disciplines to function cohesively. Key areas include:

Mechanical Engineering

Involves the design of physical structures, moving parts, actuators, gears, and systems that generate motion or perform mechanical tasks.Electrical and Electronics Engineering

Supports the integration of sensors, microcontrollers, power systems, and electronic circuits that interpret signals and power various components.Computer Science and Software Engineering

Responsible for developing the software and algorithms that control the system’s behavior, including embedded programming and real-time control logic.Control Systems Engineering

Focuses on how machines respond to inputs and maintain stability, accuracy, and performance through feedback systems and control loops.

The Mechatronic Design Process

Designing a mechatronic system requires a structured and collaborative process involving several stages:

1. Requirements Definition

Engineers begin by understanding user needs, environmental conditions, functional goals, and performance constraints.

2. System Architecture Design

This phase involves selecting the components (sensors, actuators, microcontrollers, mechanical assemblies) and defining how they will interact.

3. Modeling and Simulation

Designers create virtual models to simulate behavior and performance using tools like MATLAB/Simulink, SolidWorks, or CODESYS, allowing for optimization before building physical prototypes.

4. Hardware and Software Integration

Mechanical parts, sensors, embedded systems, and software code are integrated into a cohesive unit, ensuring compatibility and seamless operation.

5. Prototyping and Testing

Physical prototypes are built and subjected to rigorous testing. Feedback from testing is used to improve performance, safety, and reliability.

6. Production and Deployment

After successful validation, the design moves into production, with ongoing support for maintenance and potential upgrades.

Applications of Mechatronic Design

The versatility of mechatronic systems makes them ideal for a wide range of applications:

? Industrial Automation and Robotics

Robots in manufacturing plants rely on mechatronic design to handle tasks like assembly, welding, painting, and material handling with speed and precision.

? Automotive Systems

Modern vehicles use mechatronic systems in automatic braking, steering, engine control units (ECUs), and driver-assistance features.

✈️ Aerospace Engineering

Aircraft systems use mechatronics for flight control, engine monitoring, and landing gear automation.

? Medical Devices

Surgical robots, prosthetics, and diagnostic machines are examples of mechatronic innovations in healthcare that improve precision and patient care.

? Agricultural Machinery

Tractors, seeders, and drones equipped with sensors and control systems support precision farming, enhancing efficiency and yield.

? Smart Home and Building Automation

Systems like smart thermostats, automated lighting, and security systems use mechatronic design to improve comfort and energy efficiency.

Benefits of Mechatronic Design

✅ Higher Efficiency and Productivity

Integrated systems perform tasks faster and more accurately than conventional mechanical systems.

✅ Compact and Intelligent Systems

Mechatronics allows for the development of compact devices with multiple functions, reducing the need for separate systems.

✅ Improved User Experience

From adaptive cruise control in cars to robotic assistants, users benefit from intuitive and responsive technologies.

✅ Reduced Development Costs

Simulation and modeling tools help optimize designs early, reducing trial-and-error cycles and minimizing costly mistakes.

✅ Increased Reliability and Safety

With real-time monitoring and control, mechatronic systems can detect issues proactively and take corrective actions.

Tools and Technologies Used in Mechatronic Design

CAD Software (e.g., SolidWorks, AutoCAD) for mechanical modeling

Simulation Tools (e.g., MATLAB/Simulink, ANSYS) for control logic and behavior testing

Embedded Programming (e.g., C/C++, Python, Arduino, Raspberry Pi) for control systems

Microcontrollers (e.g., STM32, PIC, Arduino) for hardware integration

Sensor and Actuator Libraries for interfacing physical systems with control logic

Challenges in Mechatronic Design

Despite its benefits, mechatronic design also presents challenges:

Interdisciplinary Coordination: Requires collaboration between mechanical, electrical, and software engineers.

Complex Integration: Synchronizing all systems for real-time functionality can be challenging.

Cost of Development: High-precision sensors, components, and tools can increase initial development costs.

Maintenance and Upgrades: As systems become more complex, maintaining or upgrading components without disrupting the entire system is a key consideration.

Future of Mechatronic Design

As industries adopt smart manufacturing and the Internet of Things (IoT), mechatronic systems will play an even more significant role. The integration of AI, machine learning, and cloud computing with mechatronics will enable adaptive and predictive systems that can learn from their environment and improve performance over time.

Technologies like digital twins, edge computing, and real-time analytics are also being incorporated into mechatronic systems, pushing the boundaries of automation and smart design.

Conclusion

Mechatronic Design is not just about combining mechanical and electrical systems—it’s about creating intelligent solutions that interact with the real world in smarter ways. Whether it's enhancing automation, improving healthcare, or powering the next generation of vehicles, mechatronic engineering is a cornerstone of innovation. As industries continue to evolve, embracing mechatronic design will be key to staying competitive, efficient, and future-ready.