In today’s fast-paced industrial landscape, precision, reliability, and efficiency are key to achieving optimal performance. Whether in the plastic industry, packaging sector, or food processing, maintaining consistent temperatures is critical for both product quality and energy efficiency. This is where modern heating technologies, such as the cartridge heater with thermocouple and band heater with thermocouple, play a crucial role. These heaters not only ensure accurate temperature control but also enhance the safety and lifespan of machinery.

Understanding Industrial Heating Systems

Industrial heaters are essential components in a wide range of manufacturing processes. They provide the necessary heat to melt, mold, or process materials such as plastic, metal, or rubber. Among various types, cartridge and band heaters are particularly popular due to their versatility and high efficiency.

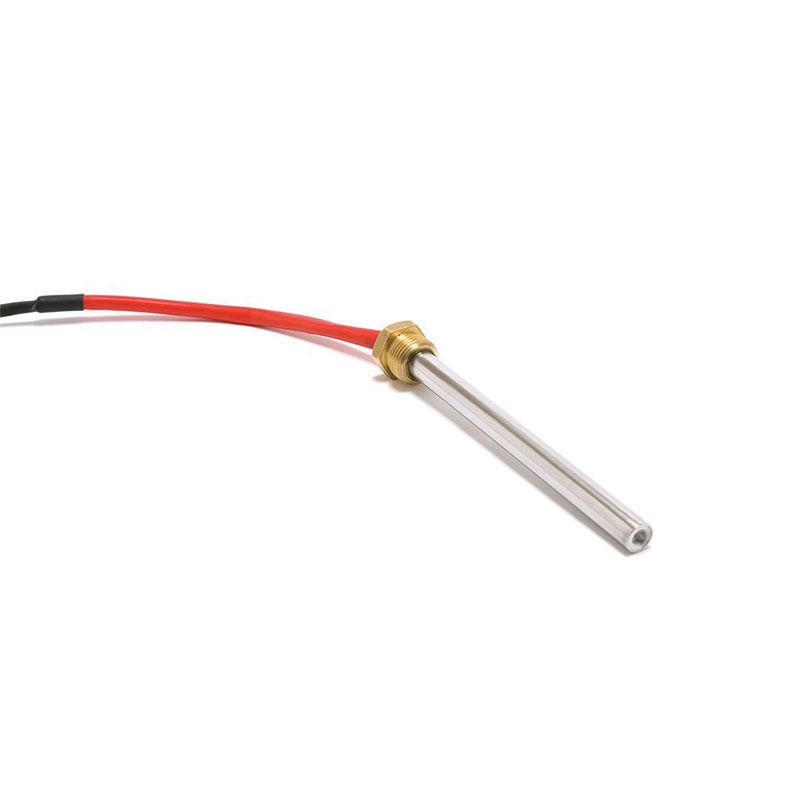

A cartridge heater with thermocouple is a cylindrical heating device designed to fit snugly into holes drilled into metal blocks or other parts that require direct heat transfer. On the other hand, a band heater with thermocouple wraps around cylindrical surfaces such as barrels, nozzles, or pipes, providing even heat distribution across the surface.

Both heaters are widely used in industries like plastics, packaging, food processing, pharmaceuticals, and injection molding, where maintaining accurate temperatures is vital to product consistency and operational efficiency.

Source : https://dheheaters.com/industr....ial-heaters/cartridg