In industrial automation, even a fraction of a second can make or break a process. Motors need to start at the right time, conveyors must run for just the right interval, and equipment has to shut down before damage occurs. That is why companies searching for a Digital Timer Relay, supplier options with experience and technical depth, make careful decisions. A digital timer relay uses an electronic circuit and LED display to provide precise control over time delays. Unlike mechanical devices, it delivers accuracy across a wide range, from milliseconds up to hundreds of hours. ATOrelays has seen how B2B customers depend on these devices for consistent operation in manufacturing, building systems, and energy management.

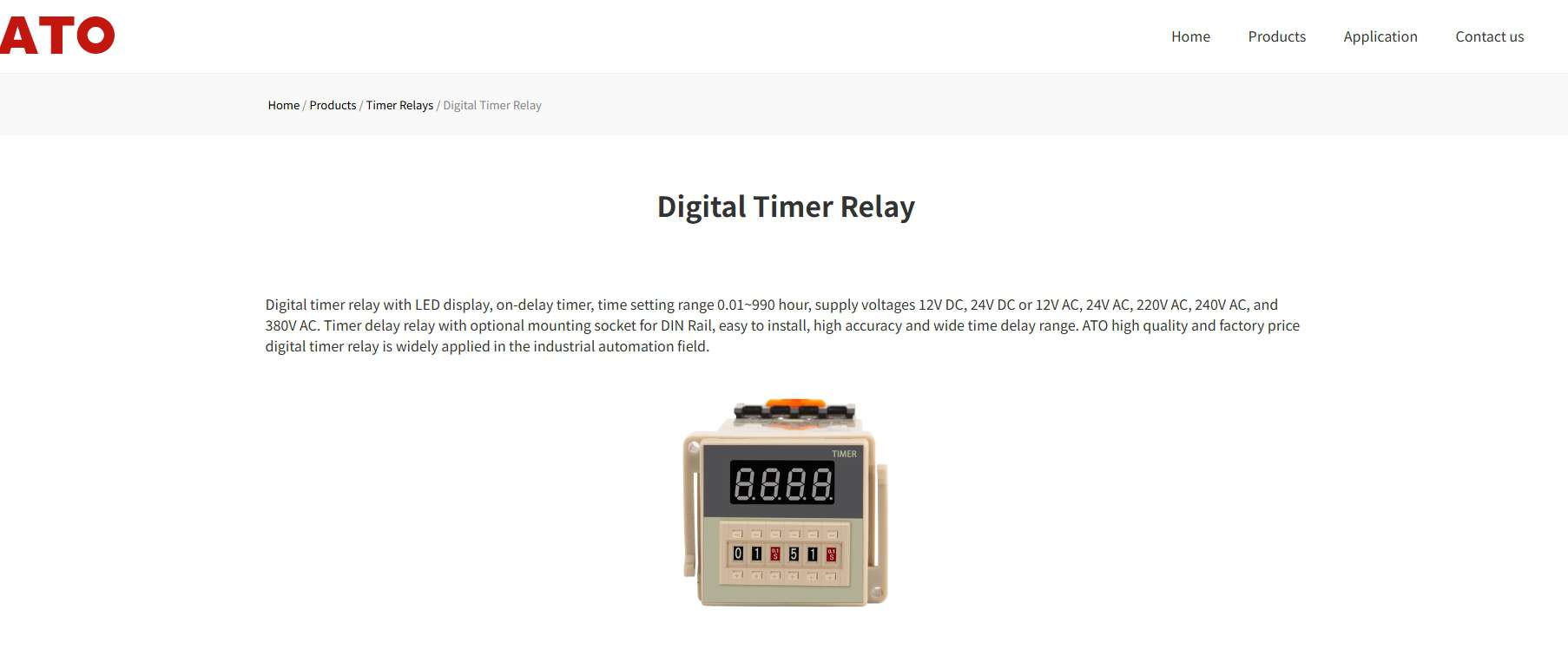

The problem many users encounter is inconsistency or complexity. Standard relays may overheat, wear out, or fail to deliver exact timing when exposed to changing loads. Mechanical timers can drift, leaving operators frustrated by small errors that accumulate into costly downtime. Digital Timer Relays solve these challenges with features like LED displays for clear settings, flexible buttons for quick adjustment, and ranges from 0.01 seconds up to 990 hours. This flexibility makes them valuable across diverse applications, whether it’s a short on-delay cycle in packaging or extended control in HVAC systems.

Unmet needs in B2B sourcing often come from compatibility. Plants operate on different voltages, and buyers cannot afford delays caused by mismatched components. That is why quality suppliers provide models that accept 12V DC, 24V DC, 12V AC, 24V AC, 220V AC, 240V AC, and even 380V AC. With DIN rail sockets for easy mounting and wiring diagrams printed directly on the device, installation is straightforward and errors are minimized. For procurement teams, this means less time troubleshooting and more time running productive lines.

The advantages of Digital Timer Relays are not just about accuracy. They are designed for durability, using copper-galvanized contacts with high conductivity and strong pin connections to ensure superior performance. Internal parts are sealed against dust and moisture, reducing the risk of environmental damage. Low heat generation keeps them stable even under long duty cycles. For B2B buyers, that translates into longer service life, lower replacement costs, and fewer interruptions to production.

From a technical perspective, modern Digital Timer Relays combine microelectronic circuits with rugged construction. They offer up to 8 adjustable time limits, ensuring operators can fine-tune settings for their specific needs. Indicators and LED displays provide instant feedback, reducing human error. Integration into automation lines is seamless, as these relays can work alongside PLCs, contactors, and control circuits. This adaptability ensures they remain relevant across industries, whether in precision manufacturing, chemical plants, or infrastructure projects.

About Us: ATOrelays has been supporting industrial clients for more than 15 years with reliable automation components. Based in the United States and partnered with global manufacturers, we supply Digital Timer Relays that meet the demands of B2B buyers across multiple industries. Our expertise, technical support, and strong supplier network ensure that businesses receive products designed for accuracy, durability, and long-term performance.