In today’s fast-paced manufacturing landscape, efficiency and precision are paramount. Automated presses have emerged as a key technology in streamlining production processes, offering significant benefits to various industries. These advanced machines are transforming how products are made, from reducing labor costs to enhancing quality control.

What Are Automated Presses?

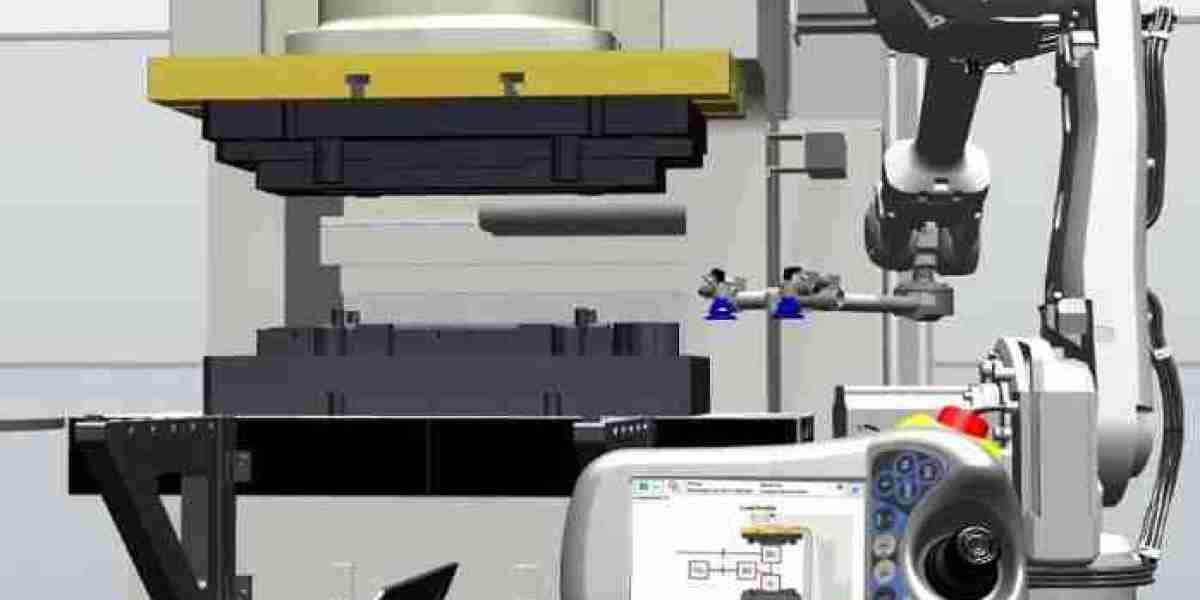

Automated presses are advanced machines designed to perform pressing operations with minimal human intervention. Equipped with sophisticated control systems, sensors, and automation technology, these presses are used for tasks such as stamping, forming, and molding. In various industries, including automotive, aerospace, and electronics, automated presses play a crucial role in ensuring high-quality production with optimal efficiency.

How Automated Presses Streamline Production Processes

Increased Production Speed

One of the most significant advantages of automated presses is their ability to increase production speed. These machines operate faster than manual presses, thanks to their advanced control systems and automation features. Automated presses can complete complex pressing operations in a fraction of the time it would take manually, allowing manufacturers to meet high production demands and keep up with market trends. Faster production cycles lead to higher output rates and improved overall efficiency.Enhanced Precision and Consistency

Precision is critical in manufacturing, and automated presses excel in this area. Equipped with advanced sensors and control systems, these presses ensure that every component is produced to exact specifications. This precision reduces the risk of defects and ensures that all parts meet quality standards. The consistency achieved through automated presses is vital for industries where even minor variations can lead to significant issues, such as in the automotive and aerospace sectors.Reduced Labor Costs

Automated presses significantly reduce the need for manual labor, leading to substantial cost savings. By automating repetitive and labor-intensive tasks, manufacturers can lower their workforce requirements and allocate resources more efficiently. This reduction in labor costs not only improves the bottom line but also allows workers to focus on more complex and value-added tasks. Automation streamlines operations, contributing to a more cost-effective production process.Improved Quality Control

Quality control is a critical aspect of manufacturing, and automated presses enhance this through precise and consistent operations. With real-time monitoring and data collection, automated presses can identify and address issues promptly. This capability allows for immediate adjustments to ensure that products meet quality standards. Automated presses often integrate with quality control systems, providing valuable data for continuous improvement and helping manufacturers maintain high standards.Minimized Material Waste

Efficient use of materials is essential for cost-effective manufacturing. Automated presses reduce material waste through precise control of pressing parameters. By minimizing excess material and optimizing resource utilization, these presses contribute to more sustainable production practices. The ability to reuse and recycle scrap material further enhances environmental responsibility and aligns with industry goals for reducing waste and promoting sustainability.Enhanced Flexibility and Adaptability

The versatility of automated presses allows manufacturers to adapt quickly to changing production requirements. These presses can be easily reconfigured to handle different product designs and specifications. This flexibility is particularly valuable in industries with diverse product lines and varying customer demands. Automated presses enable manufacturers to respond swiftly to market changes, ensuring that production processes remain agile and adaptable.Integration with Smart Manufacturing

Automated presses are integral to the Industry 4.0 revolution, which focuses on smart manufacturing and digital transformation. These presses often feature advanced connectivity and integration capabilities, allowing them to be part of a larger smart manufacturing ecosystem. Integration with data analytics, IoT (Internet of Things), and other digital technologies enhances overall production efficiency. Real-time data collection and analysis provide insights that can drive further optimization and innovation.Enhanced Safety and Ergonomics

The automation of pressing operations improves workplace safety and ergonomics. By handling repetitive and potentially hazardous tasks, automated presses reduce the risk of injuries and enhance overall safety conditions. Workers are less exposed to physical strain and unsafe working environments, contributing to a more comfortable and secure workplace. Enhanced safety measures also lead to fewer accidents and disruptions, supporting smooth and uninterrupted production processes.Reduced Downtime

Automated presses are designed to operate with minimal downtime. Advanced maintenance features, such as predictive maintenance and real-time diagnostics, help identify and address potential issues before they lead to production stoppages. These features ensure that automated presses remain in optimal working condition, reducing unexpected breakdowns and maintenance-related delays. Reduced downtime translates to more efficient production processes and higher overall productivity.Cost-Effective Long-Term Investment

While the initial investment in automated presses may be significant, the long-term benefits make them a cost-effective choice for many manufacturers. The efficiency, precision, and cost savings associated with automated presses lead to a strong return on investment. Over time, the reduced labor costs, improved quality, and enhanced productivity contribute to overall profitability and competitiveness in the market.

Future Trends in Automated Presses

As technology continues to evolve, automated presses are expected to incorporate even more advanced features. Future trends may include:

Artificial Intelligence (AI) Integration: AI-driven systems will further enhance the capabilities of automated presses, enabling more sophisticated data analysis, predictive maintenance, and process optimization.

Advanced Robotics: The integration of advanced robotics will increase the versatility and precision of automated presses, allowing for more complex and intricate operations.

Enhanced Connectivity: Continued advancements in IoT and connectivity will enable even greater integration of automated presses into smart manufacturing systems, leading to more streamlined and efficient production processes.

Sustainable Technologies: Innovations in sustainable technologies and materials will be incorporated into automated presses, supporting the industry's efforts to reduce environmental impact and promote green manufacturing practices.

Conclusion

Automated presses are revolutionizing production processes by offering increased speed, precision, and efficiency. These advanced machines are transforming how products are manufactured, leading to reduced labor costs, improved quality control, and minimized material waste. As technology continues to advance, automated presses will play an increasingly vital role in shaping the future of manufacturing. By embracing the capabilities of automated presses, manufacturers can achieve greater efficiency, productivity, and competitiveness in a rapidly evolving industry.