Performance:

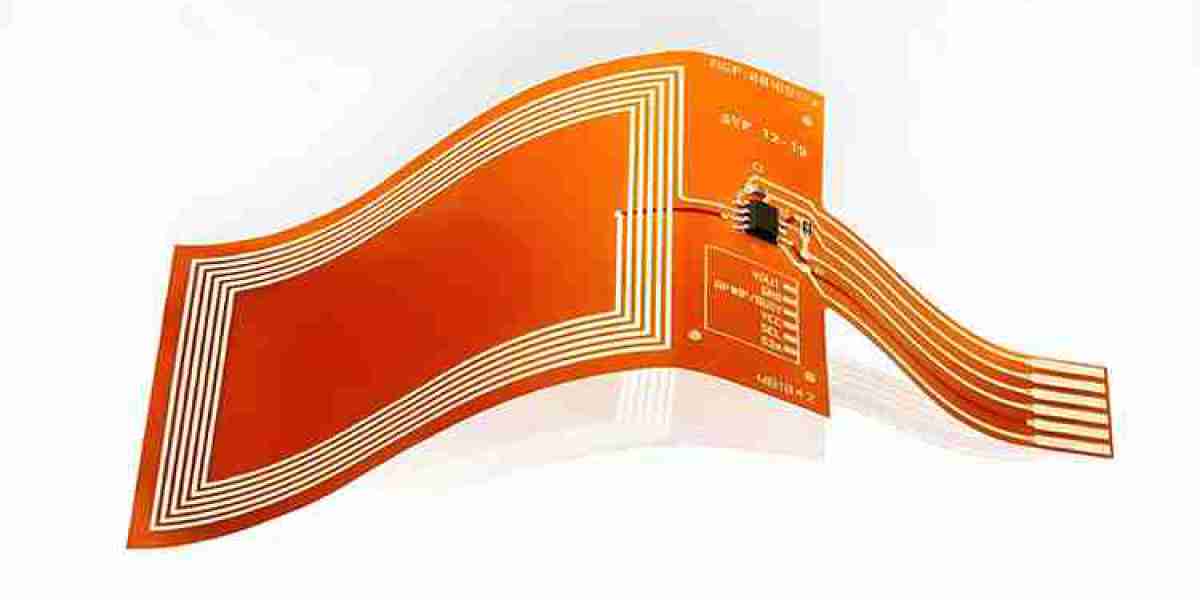

1. Flexibility for Moving Parts: Flexible PCBs excel in applications where components need to move, offering high cycle flex life for dynamic connections.

2. Versatile Assembly: Components can be assembled on a flat surface and then bent to fit the product's shape, allowing for versatile designs.

3. Easy Repairs: If necessary, flexible PCBs can be flattened for repairs, making maintenance straightforward.

4. Efficiency Boost: They significantly enhance assembly efficiency, reducing the time and effort required for complex constructions.

Cost:

1. Reduced Assembly Costs: Flexible PCBs can cut assembly costs by 20% to 50% by simplifying the wiring process compared to traditional cables.

2. Error Reduction: They lower the chances of errors in fixed connection points and orientation, simplifying inspection and rework processes.

3. Simplified Processes: Flexible PCBs eliminate the need for complex procedures like wire cutting, stripping, and handling, making the process more efficient.

While rigid PCBs offer more dimensional stability, flexible PCBs require additional processes, tools, and tolerances. Made from polyimide resin, flexible PCBs are more expensive per unit area compared to rigid PCBs. However, incorporating flexible PCBs can reduce the overall amount of rigid PCBs and cabling needed, making integration easier and improving product reliability by reducing the number of parts and connections.

Historical Evolution

Initially, flexible PCBs were mainly used as cables for point-to-point connections, often in single- or double-sided designs. These early flexible PCBs consisted of copper foil laminated onto PET or PI substrates. Over time, flexible PCBs have evolved to handle continuous dynamic flexing in various applications.

Flexible PCBs first gained prominence in U.S. military applications, with Japan being a major early adopter. By the late 1970s, flexible PCBs were used in computers, cameras, printers, car audio systems, and more. The U.S. later expanded its use to consumer electronics, including hard drives, optical drives, laptops, cell phones, and digital cameras, where their dynamic flexing capabilities are crucial.

For easier handling and dimensional stability during assembly, flexible PCBs are sometimes reinforced with backing or stiffener plates. In high-power applications, they may incorporate additional cooling techniques similar to rigid PCBs.

Due to their ability to absorb thermal expansion and contraction stresses, flexible PCBs rarely fail in fatigue tests even in direct "leadless" component connections. With the trend towards high-density assembly, flexible PCBs are not only enhancing direct chip installation feasibility but are also becoming vital in 3D assembly solutions.

Summary

The comparison between flexible and rigid-flex PCBs highlights their unique advantages and applications. Flexible PCBs, known for their high flexibility and ease of assembly, excel in dynamic environments and simplify complex designs, reducing assembly costs and errors. They also enhance maintenance and repair processes, offering significant efficiency improvements.

However, rigid PCBs provide greater dimensional stability. While flexible PCBs are typically more expensive per unit area due to their polyimide resin construction, they can reduce the overall need for rigid PCBs and cabling, thus improving product reliability. Gekunflex integrates advanced flexible PCB technology, addressing both cost and performance considerations, while continuously evolving to meet the demands of high-density and 3D assembly applications.