When it comes to piping systems, elbows are one of the most critical components. Among the various types, SR Elbows, or Short Radius Elbows, play a significant role in systems requiring tight bends and compact installations. But what exactly is an SR Elbow, how does it differ from other pipe fittings, and why is it widely used? This guide will answer these questions in a simple and informative way to give you a clearer understanding of Short Radius pipe fittings.

What is an SR Elbow?

An SR Elbow, or Short Radius Elbow, is a type of pipe fitting used to change the direction of flow in a piping system. The "Short Radius" refers to its bend radius, which equals one pipe diameter. For example, if the pipe has a diameter of 6 inches, the Short Radius Elbow forms a curve with a radius of 6 inches.

Contrasting with the long radius (LR) elbow, which has a radius of 1.5 times the pipe diameter, SR Elbows are compact and designed for tight spaces where layout constraints exist.

Key Features of SR Elbows:

- Compact Design: Perfect for installations with spatial limitations.

- Quick Direction Changes: Provides efficient flow within short distances.

- Multiple Materials: Available in carbon steel, stainless steel, alloy, and more, depending on the industry requirements.

Types of Short Radius Elbows

1. 45-Degree SR Elbow

This type of elbow forms a 45-degree bend in the pipeline. It is ideal for slightly redirecting the flow in compact piping layouts.

2. 90-Degree SR Elbow

Used to turn the piping direction by 90 degrees, this is one of the most commonly used SR Elbows. It connects pipes in a perpendicular direction efficiently.

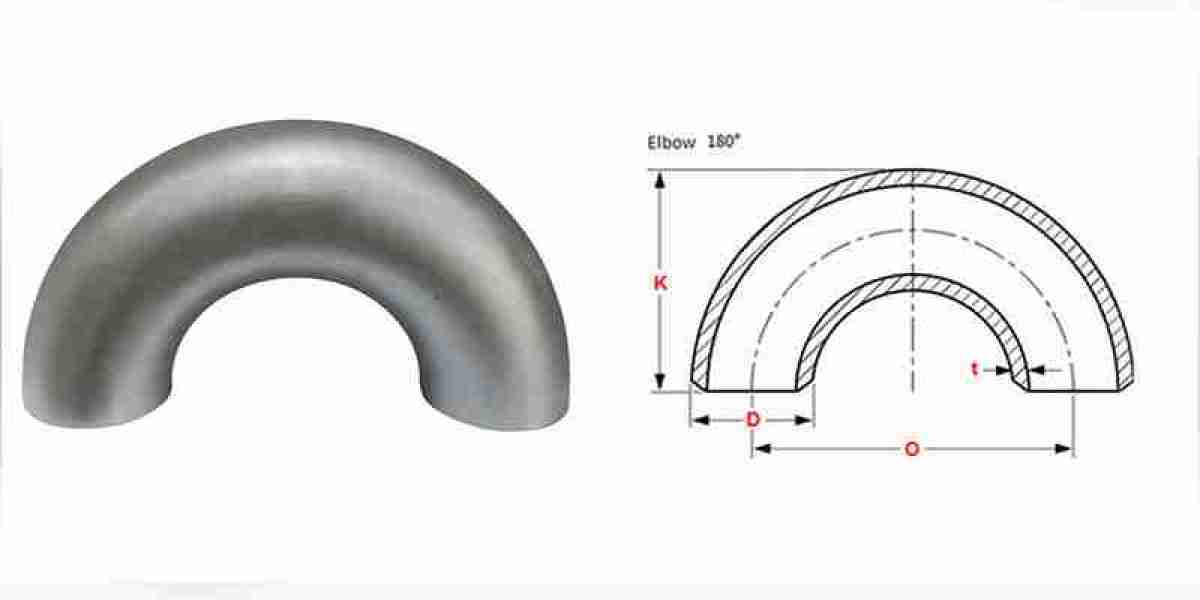

3. 180-Degree SR Elbow

A 180-degree SR Elbow is used to create a full U-turn in the pipeline. These are especially useful in heat exchangers and other industrial setups requiring flow reversal within minimal space.

4. Specialty SR Elbows

SR Elbows can also come in custom configurations, such as long weld neck or flanged ends, tailored to meet specific industry requirements.

Each type serves a unique purpose and offers flexibility in designing piping systems for compressed layouts.

Applications of SR Elbows

Short Radius Elbows are indispensable in many industries because they efficiently handle various flow requirements. Their compact design and tight turning radius make them ideal in the following applications:

1. Oil and Gas Industry

SR Elbows are extensively used in refineries and offshore drilling platforms to handle tight piping arrangements without compromising efficiency.

2. Chemical Processing Plants

These elbows help build pipelines in crowded layouts, enabling the transport of corrosive chemicals, gases, or liquids safely.

3. Power Plants

Power generation facilities rely on SR Elbows for high-pressure steam or water transportation in confined environments.

4. HVAC Systems

Short Radius pipe fittings are essential in heating, ventilation, and air conditioning (HVAC) systems to change flow direction in compact indoor spaces.

5. Marine Applications

Ships have limited room for large plumbing systems, making SR Elbows the go-to choice for seawater pipelines and fuel delivery systems aboard vessels.

Fun Fact:

SR Elbows are often paired with butt weld fittings for stronger, leak-proof connections in critical systems!

Benefits of Using Short Radius Elbows

SR Elbows provide numerous advantages that make them an ideal choice for specific installations. Here’s a closer look:

1. Space-Saving Solution

One of the primary benefits of an SR Elbow is its ability to fit into tight spaces, especially in facilities where every inch matters.

2. Smooth Flow Direction

Despite their compact size, Short Radius Elbows ensure smooth flow transitions, minimizing turbulence and pressure loss in the pipeline.

3. Cost-Efficient in Compact Systems

The use of SR Elbows reduces the need for long, curved pipes, saving on material costs and using less space.

4. Easy Installation

Their smaller size makes them relatively easier to handle and install, especially in maintenance-heavy setups.

5. Wide Material Options

SR Elbows can be made from stainless steel, carbon steel, copper, or other composite materials, making them adaptable to various temperature, pressure, and chemical conditions.

6. Versatility Across Industries

From petrochemical to food and beverage industries, SR Elbows are a critical part of every major piping application.

Final Thoughts

Looking for the leading SR Elbow manufacturer offering superior quality in India? Rajveer Stainless & Alloys are one of the Trusted & Best Manufacturer of SR Elbows & many more products. SR Elbows are indispensable in the world of piping systems, providing unmatched flexibility in compact and space-restricted environments. Understanding their different types, applications, and benefits will help you choose the right solution for your project. Whether you’re working in oil refineries, chemical plants, or HVAC systems, the proper use of Short Radius Elbows ensures efficiency, durability, and safety.