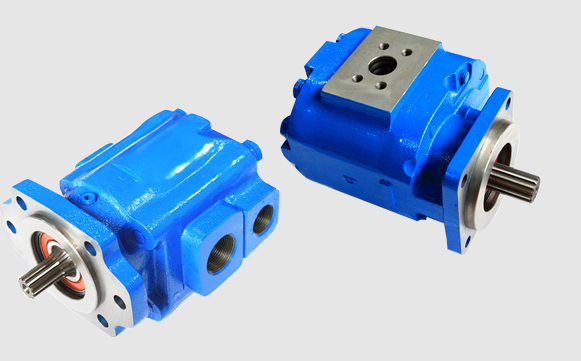

In the world of hydraulic systems, pumps play an essential role in ensuring the effective transfer of fluids and providing the necessary pressure for various machinery. Among the many pumps available on the market, the P50 pump and P365 pump stand out for their efficiency and reliability. These pumps are commonly used in a range of industrial applications, including manufacturing, construction, and automotive industries. Their performance is trusted by professionals across the globe, and their robust design makes them ideal for heavy-duty operations. Let’s dive deeper into the features and advantages of these two high-performance pumps.

Key Features of the P50 Pump

The P50 pump is renowned for its adaptability and great performance in many hydraulic applications. Designed to operate under high pressure, the P50 pump provides consistent output and is highly efficient in converting mechanical energy into hydraulic pressure. It’s ideal for use in construction, mining, and industrial applications that require heavy-duty hydraulic pumps. Additionally, the P50 pump features durable components that withstand wear and tear, making it a reliable choice for long-term operations. Its compact size and powerful output make it a top choice for professionals looking for a balance between size and performance.

Benefits of Using the P365 Pump

The P365 pump is another excellent option when it comes to hydraulic fluid transfer. Designed for precision and durability, the P365 pump offers high efficiency and smooth operation even in demanding conditions. Whether you are dealing with low or high-pressure systems, the P365 pump is equipped to handle it all. One of the standout benefits of the P365 pump is its low maintenance requirements, ensuring reduced downtime for operators. Its advanced features also include enhanced safety measures that prevent overloading and ensure smooth functioning even in the most challenging environments, making it a valuable addition to any industrial toolkit.

Differences Between the P50 and P365 Pumps

While both the P50 pump and P365 pump share similar core functionalities, there are key differences that make them suited for different types of operations. The P50 pump is ideal for high-flow applications, especially when there is a need for consistent output over an extended period. On the other hand, the P365 pump is designed for precision, making it more suitable for applications where accuracy and low-pressure systems are critical. While the P50 is more versatile in handling various flow rates, the P365 stands out for its low maintenance and longer service life under less demanding conditions.

Why Choose the P50 or P365 for Your Project

Choosing between the P50 pump and the P365 pump comes down to your specific project requirements. If your operations require high efficiency and high flow for demanding tasks, the P50 pump would be a suitable choice. On the other hand, if your project demands precision, low maintenance, and long-lasting performance in less harsh environments, the P365 pump may be a better fit. Both pumps are highly reliable, but selecting the right one depends on factors such as pressure requirements, operational environment, and frequency of use.Understanding these distinctions can help you make an informed decision that maximizes your project’s success.

Conclusion

When it comes to choosing the right hydraulic pump for your industrial needs, the P50 pump and the P365 pump are both excellent options. Whether you prioritize high-flow efficiency or precision performance, both pumps are designed to meet the demands of tough, high-pressure systems. For a wide range of hydraulic solutions, Terrekosen Hydraulic offers quality products that ensure smooth and effective operation. Visit terrekosen-hydraulic.com to explore their offerings more and choose the ideal pump for your next project.