The manufacturing of tank brush making, essential tools for various industries, has undergone a remarkable transformation over the years. At the heart of this evolution are tank brush making machines, which have revolutionized production methods, enhanced efficiency, and improved product quality. This article delves into the history, technology, and future prospects of tank brush making machines, highlighting their significance in modern manufacturing.

A Brief History of Tank Brushes

Traditionally, these brushes were handmade, requiring skilled artisans to carefully assemble each component. While this ensured quality, it also limited production capacity and scalability.

The introduction of machinery in the 20th century marked a turning point. Early tank brush making machines utilized simple mechanical processes, gradually evolving into the sophisticated systems we see today. This evolution reflects broader trends in manufacturing, where automation and precision engineering have become paramount.

Key Features of Modern Tank Brush Making Machines

Precision Manufacturing

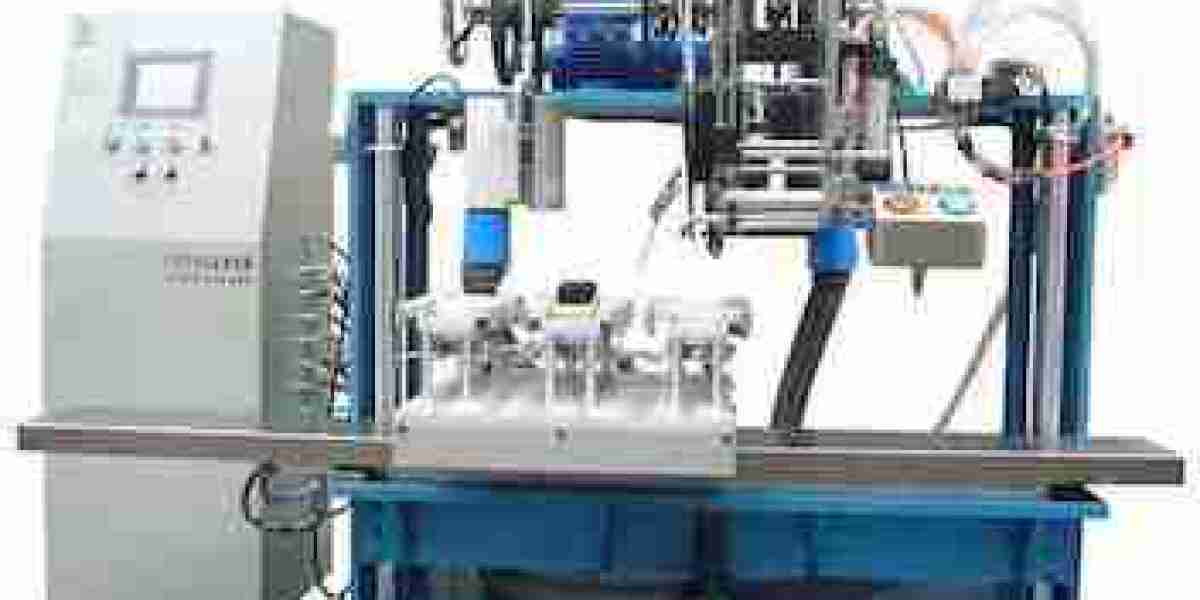

Modern machines utilize advanced technologies such as CNC (Computer Numerical Control) to ensure each brush is produced with exact specifications. This precision guarantees that the brushes meet industry standards for effectiveness and durability.

High-Speed Production Capabilities

Contemporary tank brush making machines are designed for high-speed production. With the ability to produce thousands of brushes daily, manufacturers can meet growing demand efficiently.

Customization Options

Many machines now offer customization features, allowing manufacturers to create brushes tailored to specific applications. This flexibility enables companies to cater to diverse customer needs, from industrial cleaning to specialized applications.

Automation and Robotics

The integration of automation and robotics has streamlined the production process. Automated systems reduce the need for manual labor, increasing efficiency while minimizing human error.

Eco-Friendly Manufacturing

Innovations in manufacturing technologies have led to more sustainable practices. New machines consume less energy and use eco-friendly materials, aligning with the increasing demand for environmentally responsible products.

Benefits of Tank Brush Making Machines

The advancements in tank brush making machines provide numerous advantages that enhance both production and product quality:

Improved Efficiency

Automated manufacturing processes significantly increase production rates, allowing companies to meet market demands promptly. This efficiency helps businesses reduce lead times, ensuring that customers receive their orders quickly.

Consistent Quality Control

Modern machines are equipped with sophisticated quality control mechanisms. These features allow manufacturers to monitor production in real-time, identifying defects early in the process. As a result, only the highest quality brushes reach the market.

Cost-Effectiveness

The automation of production processes helps lower labor costs and reduces waste, ultimately resulting in cost savings for manufacturers. These savings can be reflected in lower prices for consumers, making high-quality tank brushes more accessible.

Adaptability to Market Changes

The ability to quickly adjust production lines in response to changing market demands is a significant advantage of modern tank brush making machines. Manufacturers can swiftly launch new products or modify existing ones to meet evolving customer preferences.

The Future of Tank Brush Making Machines

As technology continues to advance, the future of tank brush manufacturing holds exciting possibilities:

Smart Manufacturing

The integration of smart technologies, such as the Internet of Things (IoT), is set to revolutionize the industry. Smart machines will be able to communicate with each other and with manufacturers, optimizing production processes and improving overall efficiency.

Sustainability Focus

With increasing awareness of environmental issues, the future will likely see a stronger emphasis on sustainable manufacturing practices. Innovations in materials and processes will help create eco-friendly tank brushes, catering to environmentally conscious consumers.

Enhanced Personalization

As consumer preferences shift towards personalized products, tank brush making may incorporate features that allow for greater customization. This capability will enable manufacturers to produce brushes tailored to specific industries and applications, enhancing customer satisfaction.

Follow Us On More Links:-

Follow Us On Facebook:- https://www.facebook.com/people/Habito-Designs/100064230276942/

Follow Us On Instagram:- https://www.instagram.com/habitodesigns/

Follow Us On Linkedin:- https://www.linkedin.com/company/habito-designs

Address:- 20 Silistria Cl, Knaphill, Woking GU21 2TL, United Kingdom

Email Us:- enquiries@habitodesigns.com

Contact Us:- 07726 313 993