Transforming Predictive Maintenance with Computer Vision

Computer vision is revolutionizing predictive maintenance by enabling businesses to identify potential equipment failures before they occur, reducing downtime and enhancing operational efficiency. This cutting-edge technology leverages AI-driven image analysis to monitor machinery, detect anomalies, and predict maintenance needs in real time. By integrating computer vision into predictive maintenance strategies, industries such as manufacturing, transportation, and energy are streamlining operations and minimizing costly disruptions.

Using high-resolution cameras and sensors, computer vision systems continuously capture visual data from equipment. AI algorithms analyze this data to detect signs of wear and tear, overheating, leaks, or misalignments that are invisible to the human eye. These insights allow maintenance teams to address issues proactively, preventing unexpected breakdowns and extending the lifespan of assets.

One of the key advantages of computer vision in predictive maintenance is its ability to work in diverse environments. From monitoring conveyor belts in manufacturing plants to inspecting turbines in wind farms, the technology adapts to various operational scenarios. It also integrates seamlessly with Internet of Things (IoT) devices, creating a robust ecosystem where visual data combines with sensor readings to provide comprehensive equipment health assessments.

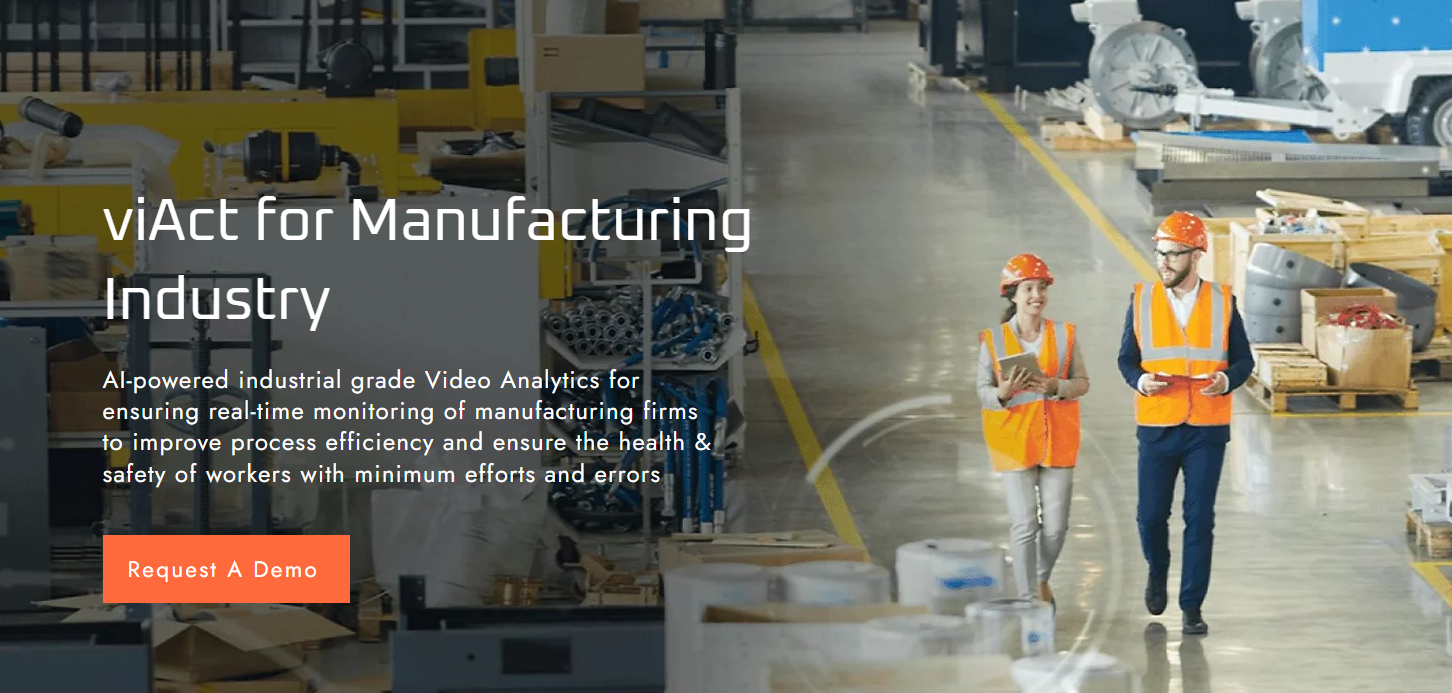

https://www.viact.ai/manufacturing