In manufacturing and production, precise and effective instructions are crucial for smooth assembly processes. Traditional printed manuals, often dense and static, have been replaced by more dynamic solutions, such as 3D assembly technology and 3D assembly manual software, offering detailed, interactive guides that enhance productivity and accuracy. This article explores how these 3D innovations are reshaping the way assembly tasks are executed, making processes faster, clearer, and more efficient.

The Benefits of 3D Assembly for Modern Manufacturing

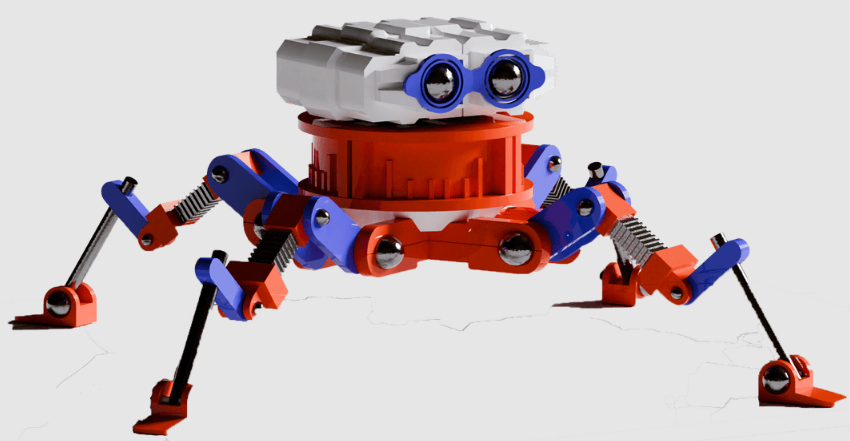

3D assembly introduces a new way of visualizing and executing assembly tasks by providing interactive, detailed 3D models of components and assembly steps. Unlike flat, printed diagrams, 3D models can be rotated, zoomed, and explored from multiple angles, allowing workers to understand each part of the assembly process fully. This depth of visualization reduces the chances of mistakes, ensuring that every step is accurately followed.

Incorporating 3D assembly tools helps manufacturers address the increasing complexity of modern products, where precision and detail are vital. With the help of 3D assembly technology, production lines become more efficient as workers can quickly grasp intricate processes without having to interpret complex paper manuals. Additionally, 3D assembly minimizes the need for extensive training, enabling new workers to learn assembly procedures more quickly.

Why a 3D Assembly Manual is Essential

A 3D assembly manual provides the ultimate interactive guide for assembly tasks. Unlike standard manuals, a 3D assembly manual offers step-by-step instructions in a digital, 3D format that’s accessible across devices like tablets, smartphones, and computers. This format includes detailed animations, interactive steps, and helpful annotations that make it easy for users to follow each phase of the assembly accurately.

The manual’s flexibility is beneficial for businesses with frequently updated products, as adjustments can be made instantly, ensuring that all workers have access to the latest instructions. By using a 3D assembly manual, manufacturers improve the speed and accuracy of assembly, reduce downtime, and foster a more agile production environment. Furthermore, it streamlines troubleshooting, as workers can review specific steps visually rather than flipping through pages of a printed manual.

How 3D Manuals Improve Quality and Efficiency

Combining 3D assembly tools with a 3D assembly manual creates a powerful framework that supports both quality control and production efficiency. These digital manuals not only provide clear, detailed instructions but also allow managers to track and analyze usage data. This information helps businesses identify areas where assembly processes can be optimized, improving productivity and consistency.

For manufacturers in industries where accuracy is crucial, such as automotive, aerospace, and electronics, 3D assembly manual offer an invaluable resource. By reducing errors, these manuals ensure that products meet high standards and reduce the need for rework, saving both time and resources. The real-time feedback and analytics further enhance operational insights, supporting continuous improvement on the production line.

Conclusion

With 3D technology, the assembly process is becoming more interactive, accurate, and user-friendly. By integrating 3D assembly and using an advanced 3D assembly manual, businesses can streamline production, reduce errors, and enhance overall efficiency. For those seeking comprehensive 3D assembly solutions, easemble.com offers specialized software designed to meet the unique needs of modern manufacturing, providing digital tools that transform the way assembly tasks are managed and executed.

FOR MORE INFO :-

printed circuit board assembly