We combine the business's greatest paint with our passion for element to exceed your expectations. Priming the metal surface is essential for effective adhesion and rust inhibition. For non-ferrous metals, contemplate a common metal primer, while for ferrous metals, alkyd primers are often recommended. Since storage tanks are confined areas, they require the presence of a gap watch.

Committed to protecting our most precious resource

Our recommendation for most of our canal boat prospects or boat house owners with comparable tanks can be to scrub these tanks as greatest you can removing any loose paint and rust. Once clear and dry apply several coats of our SML Ballastic Epoxy paying explicit attention to the sides and corners. Then, solely use these tanks for washing up water, bathrooms and so on and install a smaller accredited plastic water tank with its personal pump for ingesting water. By following these steps, you will effectively prepare the exterior floor of your steel water tank for painting, making certain that the model new paint job shall be long-lasting and aesthetically pleasing. Because this matter can actually be a lot to digest, the American Water Works Association (AWWA) offers quite lots of useful resources, together with the AWWA D guide for coating steel water-storage tanks. This guide covers every thing from pre-construction primer choices, to several sorts of interior and exterior coating methods. For the purposes of this weblog post, Section 4.three for Exterior Coating Systems offers seven coating system options with mil thicknesses, generally ranging from 5.5 to 6.5 mils.

2. Technological process of applying the corrosion protection coating:

Galvanized and Stainless Steel Rainwater Tanks made in Dripping Springs

Galvanized and Stainless Steel Rainwater Tanks made in Dripping Springs All Cuplock system scaffolding supplies are examined and authorized to worldwide scaffolding standards. Pressure vessels are designed to operate safely at a selected strain and temperature, technically referred to as the "Design Pressure" and "Design Temperature". A vessel that's inadequately designed to handle a excessive pressure constitutes a really important safety hazard. The wide range of cuplock scaffolding parts permits it to be used with typical scaffolding panels or beams.

Tanks over a thousand gallons are transported upright and received't fit in a regular decide up. a thousand gallon or much less can transport on their aspect and will slot in a full size pick up, though the tailgate might have to be lowered. Southern Tank manufactures vertical storage tanks to both the UL 142 and API 650 standards. We store construct our vertical tanks in capacities starting from 150 to 30,000 gallons when constructing to the UL 142 normal and in capacities as much as 35,000 gallons when building to the API 650 commonplace. The most diameter of our vertical tanks is 12 feet with a most shell peak of 35 feet if UL 142 and 12 toes by forty five ft if API 650. Texas Metal Tanks is proud to manufacture the best trying and highest high quality tank for your rainwater or nicely water storage wants.

Galvanized Tanks v Poly Tanks

We supply 6 totally different standard liners obtainable, caixa dagua metalica 5000 litros including coating and flexible liners, as well as custom and specialty liners for your corrugated metal water tank. For over one hundred years, corrugated galvanized steel tanks have been the preferred alternative for safe, reliable, and cost-effective water storage. Chosen by wineries, agricultural, and residential users for their vintage aesthetic, Classic Corrugated tanks mix fantastically with all kinds of architecture while providing top-of-the-line engineered life-cycle value values in the business. In addition to manufacturing tanks for over 40 years, American Tank can also be a General Engineering Contractor that is licensed to construct tanks and foundations in California, Nevada, Xiamenyoga.Com and Washington. All our tanks embrace Wet-Stamped Engineering and are put in onsite by our own manufacturing facility certified installation crew. Many of our tanks may even be installed on a easy gravel ring basis without the need for expensive concrete foundations and costly sitework.

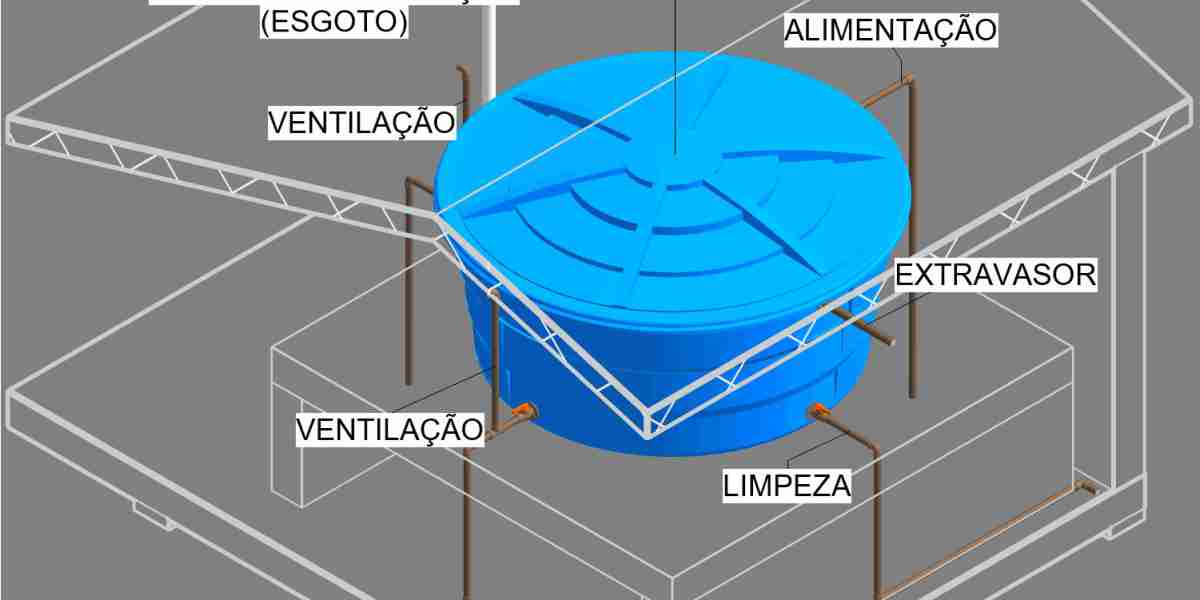

By the time you undergo all the trouble, you should in all probability clean it anyway. Galvanized roof purlins are stored out of the stored water to extend the life of the tank roof cowl. On normal galvanized tank designs, the coating of the tank shell doesn’t imply a discount of the galvanized zinc coatings, the epoxy and polyester coatings are in addition to the galvanizing process. The reservoir takes the form of a vertical cylinder with a conical bottom. A clean transition joint exists where the vertical aspect wall meets the conical bottom.

(5,000 – 102,000 Gallons)

(5,000 – 102,000 Gallons) You may choose to put in your corrugated water tank yourself or we can set up your tank with professional installers at your site. Find out more about our obtainable installation groups and engineering package deal. Stainless metal is broadly thought-about superior to other materials in the classes of power, sturdiness, and hygiene. Manufacturing tanks from stainless steel maximizes your tank’s anticipated life expectancy. When hygiene, durability and general peace of mind are paramount, there isn't any various to a Stainless Steel Rainwater Tank. Southern vertical tanks are manufactured to the UL 142 or API 650, appendix J standards for shop-built tanks.