Introduction

As the electronics industry continues to trend towards slimmer and more practical designs, Flexible Printed Circuits (FPC) have become essential components due to their superior structural design and performance. Ensuring the quality of these flexible circuits is crucial for achieving optimal application results. Implementing effective quality control measures is key to maintaining high standards for FPC manufacturers. Here, we explore the essential methods for quality control and how Gekunflex ensures its FPC products meet the highest standards.

1. Evaluating Cost-Effectiveness and Value

In the realm of circuit design, particularly in China, there are numerous methods for internal circuit connections. High-quality FPC manufacturers, like Gekunflex, emphasize analyzing flexible circuits' cost-effectiveness and return on investment. In complex systems with diverse signal processing and electrical requirements, selecting flexible PCBs can streamline device design and enhance stability. Manufacturers can ensure superior assembly results and optimized performance by choosing the right FPC.

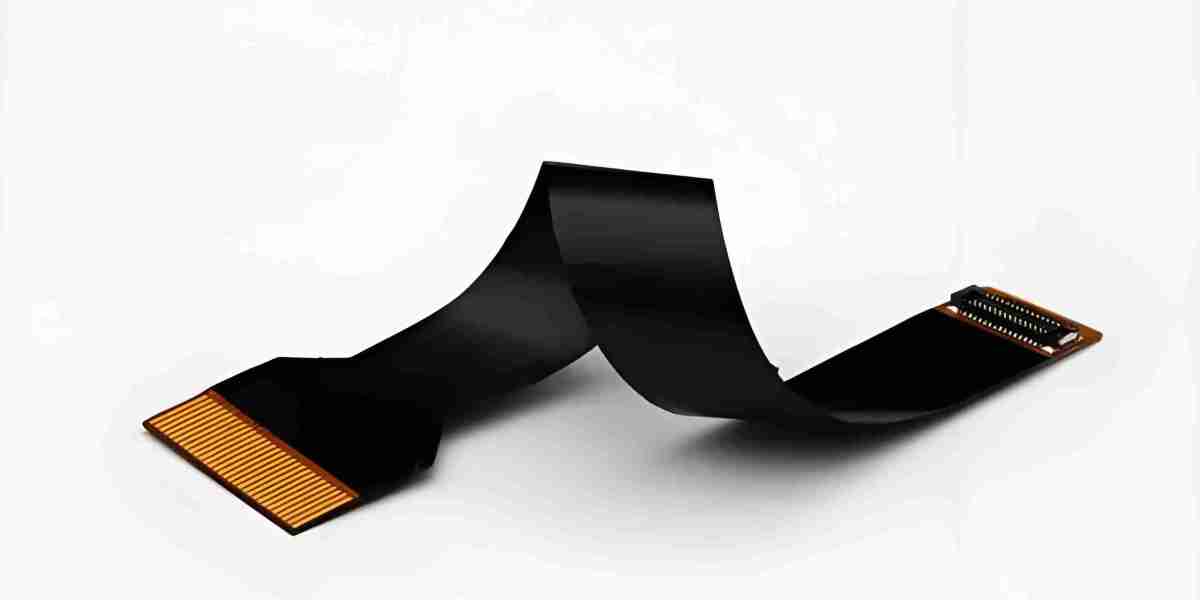

2. Assessing Flexibility and Bendability

The demand for flexibility in circuits varies across different products. High-quality FPC manufacturers offer a range of products with varying degrees of bendability. For optimal performance, it is essential to select FPCs that provide excellent flexibility without compromising on practicality. Gekunflex's products are designed to showcase their unique flexible properties, ensuring that the chosen circuit board meets the specific needs of the application.

3. Future Innovations in FPC Technology

The future of FPC technology is set to advance in four key areas:

- Thickness: Future FPCs must be even thinner to accommodate evolving design requirements. This innovation will lead to more compact and efficient designs.

- Bend Resistance: Enhanced bend resistance is crucial, with FPCs expected to withstand over 10,000 bending cycles. Achieving this requires advanced substrate materials to maintain durability.

- Pricing: Currently, FPCs are significantly more expensive than traditional PCBs. Reducing costs will expand market opportunities and make FPCs more accessible.

- Process Improvement: To meet diverse requirements, FPC manufacturing processes must advance, achieving higher standards for minimum hole diameters and line widths/spacing.

Conclusion

For FPC manufacturers like Gekunflex, ensuring the quality of flexible circuit boards involves a comprehensive approach. This includes evaluating cost-effectiveness, assessing flexibility, and focusing on future innovations. By prioritizing these aspects, manufacturers can deliver high-quality FPCs that enhance electronic device performance and reliability. Embracing these quality control methods and innovations will ensure that FPCs continue to meet the demands of modern electronics and provide excellent returns on investment.