Introduction

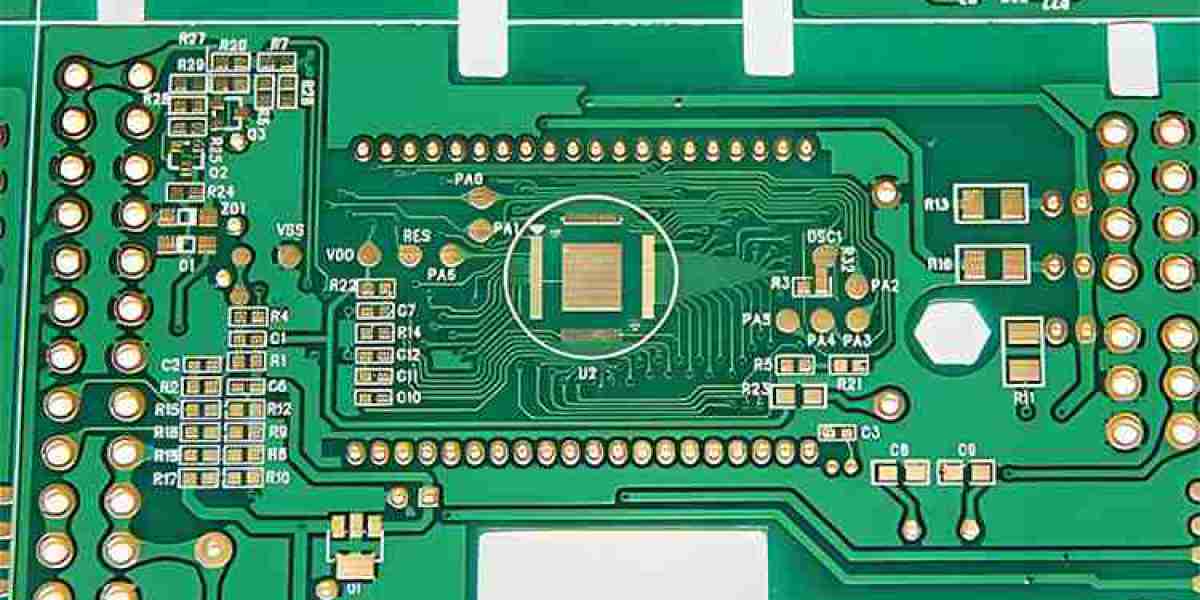

High-quality rigid circuit boards are essential for ensuring the reliability and performance of electronic devices. Understanding the key characteristics of a top-tier PCB can help manufacturers and engineers make informed decisions during the design and production processes. This article will explore the critical features of superior PCBs, highlighting their benefits and the risks associated with neglecting these factors.

1. 25-Micron Copper Thickness in Hole Walls

Benefits: Enhances reliability, particularly by improving resistance to expansion along the Z-axis.

Risks of Non-Compliance: Failure to maintain this copper thickness can lead to a variety of issues, such as blowholes or voids during assembly, electrical continuity problems (e.g., inner layer separation or hole wall cracks), and potential failures under operational stress. The IPC Class 2 standard, commonly adopted by most manufacturers, allows for 20% less copper, increasing the risk of these failures.

2. No Solder Repairs or Wire Jumper Fixes

Benefits: Ensures perfect circuit reliability and safety, eliminating the need for repairs and associated risks.

Risks of Non-Compliance: Improper repairs can cause circuit board breaks. Even well-executed repairs may result in failures under stress conditions, such as vibration, potentially leading to operational failures in real-world applications.

3. Strict Control of Surface Finish Lifespan

Benefits: Ensures solderability, reliability, and reduces the risk of moisture ingress.

Risks of Non-Compliance: Surface finish changes over time can lead to solderability issues. Moisture ingress may cause delamination, inner layer separation, or hole wall separation (breakage) during assembly or in actual use, particularly with older PCBs.

4. Copper-Clad Laminate Tolerances Meeting IPC 4101 Class B/L Requirements

Benefits: Strict control over dielectric layer thickness minimizes deviations in expected electrical performance.

Risks of Non-Compliance: Electrical performance may not meet specified requirements, leading to significant variability in output/performance within the same batch of components.

5. Defined Solder Mask Materials Meeting IPC-SM-840 Class T Requirements

Benefits: High-quality ink ensures the safety and adherence of the solder mask, meeting UL standards.

Risks of Non-Compliance: Inferior ink can lead to issues with adhesion, solvent resistance, and hardness. These problems can cause the solder mask to separate from the PCB, resulting in copper circuit corrosion. Poor insulation characteristics can lead to unintended electrical connectivity or arcing, potentially causing short circuits.

Conclusion

Ensuring that PCBs meet these stringent requirements is crucial for maintaining their reliability and performance in various applications. By focusing on these critical aspects, manufacturers can produce PCBs that not only meet but exceed industry standards, reducing the likelihood of failures and enhancing the overall quality of the end product. Gekunflex is committed to delivering high-quality PCBs that adhere to these exacting standards, ensuring superior performance and reliability in every product.