Introduction

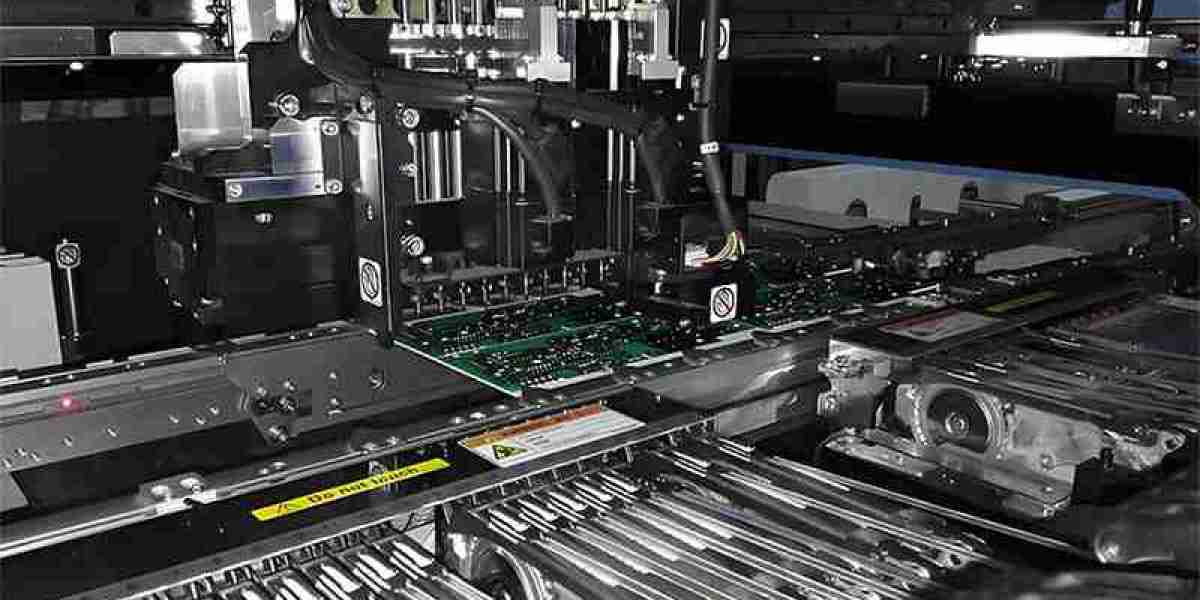

As electronic products increasingly trend towards lightweight and practical designs, flexible printed circuit (FPC) products have become indispensable components in modern electronics due to their superior product strength and better structural design. To ensure the effective application of these flexible circuit boards, FPC manufacturers believe that proper selection methods must be employed.

Quality Control Methods of FPC Manufacturers

1. Consider the Economic and Cost Value of the Circuit

In the current circuit design landscape, internal circuit connections vary widely. Reputable FPC manufacturers emphasize that when selecting flexible circuits, it is crucial to analyze the actual input-output ratio of these circuits in the specific application scenario. In cases where the circuit is complex and involves diverse signal processing and electrical systems, choosing flexible circuit boards can streamline the equipment's design. This approach also enhances the stability of the circuits produced by FPC manufacturers, ensuring that the selected flexible circuit board offers optimal assembly performance.

2. Consider the Circuit Board's Reliable Flexibility

The flexibility requirements for circuits differ across various product manufacturing processes. Within the sales of high-quality FPC manufacturers in China, there is a wide range of products with unique and varied flexural properties. To ensure a better selection, FPC manufacturers suggest that the choice should be grounded in both economic feasibility and practical utility. This ensures that the selected circuit board exhibits superior flexibility, allowing the FPC to highlight its distinctive characteristics during actual use.

Conclusion

In conclusion, FPC manufacturers must ensure that the selected circuit board products possess excellent circuit design capabilities. This involves assessing the application environment and the fundamental advantages of the product to determine the scenarios where it can be effectively utilized. Only when the product is cost-effective and provides reliable returns can FPC manufacturers analyze the long-term benefits their products may offer. This foundation ensures the reliability and authenticity of the selection process. By following these principles, Gekunflex brand products are well-positioned to lead the market with their reliable quality and innovative design, solidifying their place in the competitive landscape of flexible circuit board manufacturing.